Exhibition introduction

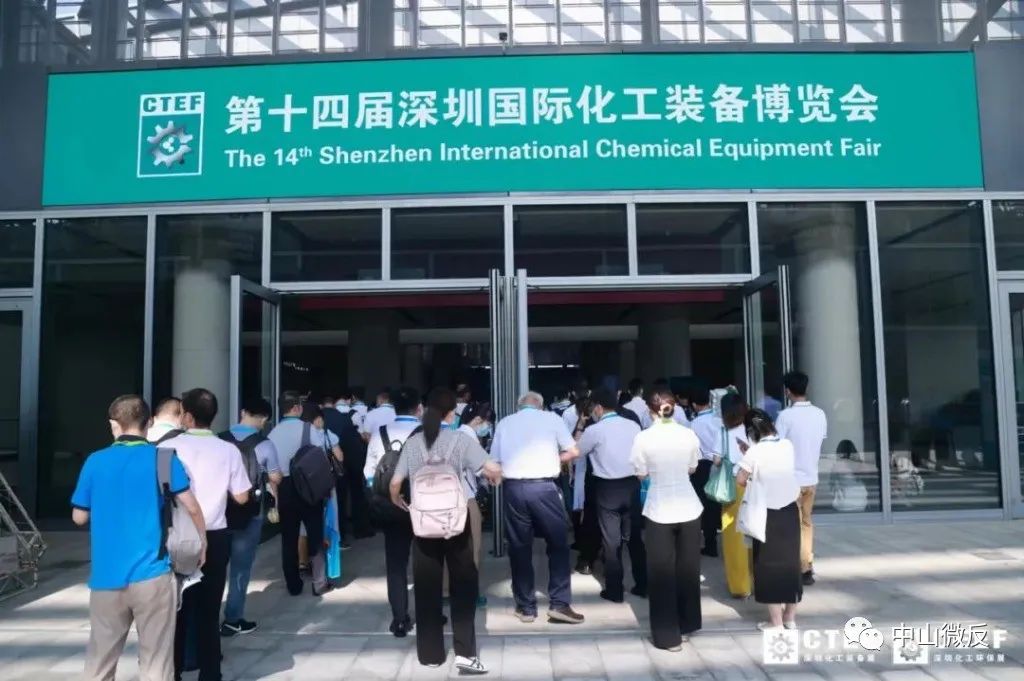

From July 28 to 29, "CTFE the 14th Shenzhen International Chemical Technology and equipment exhibition" and "the 13th International Chemical Pharmaceutical summit - CIS Asia 2022" were held in Shenzhen and Suzhou at the same time.

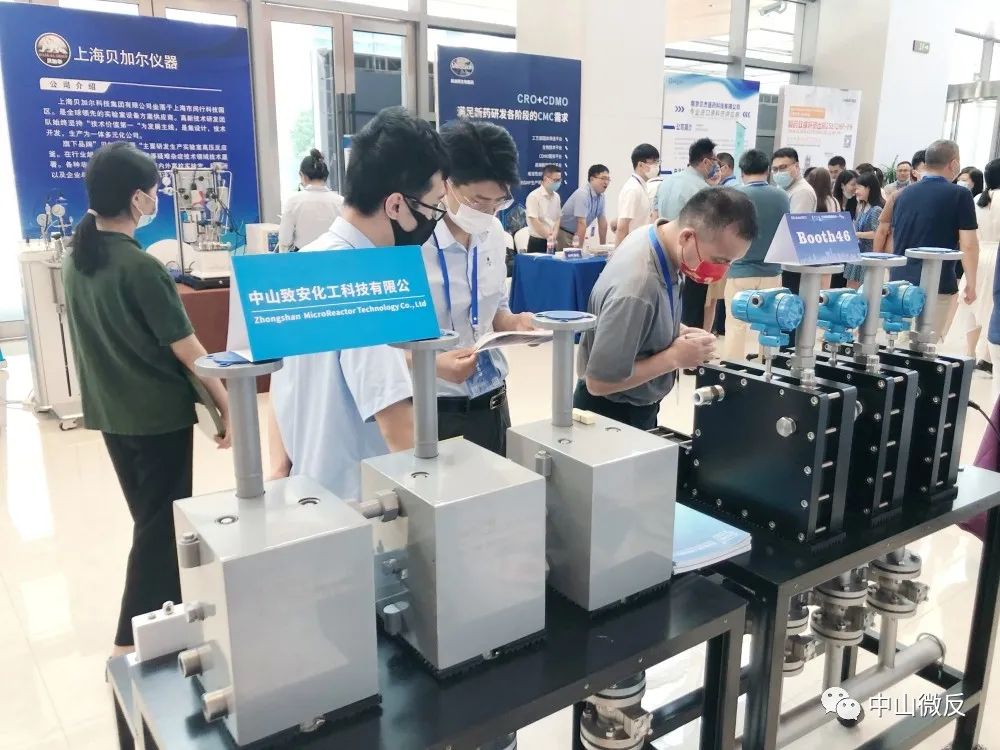

exhibition scene.

Dr. Zhu Baofu of Zhongshan Zhian Chemical Technology Co., Ltd. was invited to participate in the "Shenzhen CTFE Exhibition" and made a report entitled "innovation and application of high-throughput industrial micro reaction and linear pump technology" at the conference site. At the same time, our professional technicians Ma Rucheng and Li Yu Junjie took our micro reaction equipment to participate in the "CIS Asia 2022 Suzhou" equipment exhibition.

In the past, it required a huge investment of millions or tens of millions of yuan, and it was difficult to realize the production capacity of more than 100 tons in a single step. With the emergence of Zhongshan Zhian upgraded micro reaction equipment, a single set of micro reaction equipment with a throughput of 10000-50000 tons / year provides the possibility of low-cost investment.

The 3D printing team with Yan Xingchen, associate researcher of the Institute of new materials of the Guangdong Academy of Sciences, and Dr. Dong Dongdong as the core has, after years of technological innovation and practical precipitation, the strongest batch delivery capacity of 3D printing high-pressure micro reactor with large volume in the industry, which can realize gas-liquid, liquid-liquid and liquid-solid reactions and is suitable for 40% chemical reaction synthesis.

Taking the integral molding reactor with a volume of 2l / piece as an example, it can easily replace one or more sets of 2M ³、 3m ³、 5m ³、 10m ³ And above, the manufacturing cost is only 200000 yuan / set. In addition, Zhongshan micro reactor combines the DCS and SIS control systems of Zhejiang central control, and the complete set of micro reactor equipment can realize remote one key operation without manual operation on site.

At the same time, the high-throughput silicon carbide micro reactor with a liquid holding capacity of 1 ~ 2L jointly launched by Sanchi ceramics and Zhongshan Zhian can also control the cost of a single piece to 200000 yuan / piece, and the price of industrial micro reactors meeting most reaction types will drop sharply.

The competitiveness of chemical synthesis fundamentally depends on the synthesis route. With the upgrading of micro reaction equipment, the micro reaction equipment with high production capacity and high yield is the final factor that determines the pricing power of products. While the micro reactor realizes safety, miniaturization and universality, the structural advantages of the reactor, accurate feeding system, adjustable pressure drop flow channel and chemical synthesis experience will directly affect the operation efficiency of the micro reactor project.

Future plans

In order to let more fine chemical synthesis enterprises know about Zhongshan micro reaction technology, Zhongshan Zhian will make use of the advanced manufacturing equipment of Guangdong Academy of Sciences and three responsibility ceramics to give greater advantages in the price of 30000-60000 yuan / set of laboratory microchannel equipment and three plunger linear flow constant flow metering pump